Performance of Concrete with Marble Dust as Supplementary Material: A Review

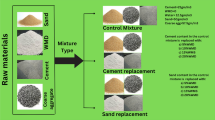

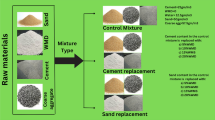

Waste marble powder is an inert material obtained from the sawing, shaping and polishing of marble. Those marble dusts are hazardous to the health and atmosphere if it is not disposed properly. The main objective of the paper is to use those powders in construction work as a supplementary material and to observe the performance in concrete. Presently, in this paper, physical, chemical, mechanical properties such as workability, compressive strength, tensile strength and durability such as water absorption by immersion, carbonation properties of concrete with marble dust are studied. The review indicates that in concrete industry marble dust can be used as replacement of sand and it generally improves the mechanical properties of concrete with lower water–cement ratio. In hydration process, marble dust does not play any role but it shows filler effect in concrete and also it shows better performance. Hence, marble dust can be used as an appropriate fine aggregate material for sustainable concrete.

This is a preview of subscription content, log in via an institution to check access.

Access this chapter

Subscribe and save

Springer+ Basic

€32.70 /Month

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Buy Now

Price includes VAT (France)

eBook EUR 234.33 Price includes VAT (France)

Softcover Book EUR 295.39 Price includes VAT (France)

Hardcover Book EUR 295.39 Price includes VAT (France)

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Use of Waste Marble Dust and Waste Glass Powder and Bacterial Solution for Manufacture of Ecofriendly Concrete

Chapter © 2023

Study on the Effect of Marble Dust as Partial Replacement to Cement with Steel Fibre in Concrete

Chapter © 2024

Utilization of waste marble dust as cement and sand replacement in concrete

Article Open access 23 May 2024

References

- Bilgin N, Yeprem HA, Arslan S, Bilgin A, Gunay E, Marsoglu M (2012) Use of waste marble powder in brick industry. Constr Build Mater 29:449–457 ArticleGoogle Scholar

- Pathan VG, Pathan MG (2014) Feasibility and need of use of waste marble powder in concrete production. J. Mech. Civil Eng, 23–26 Google Scholar

- Aruntas HY, Gürü M, Day M, Tekin I (2010) Utilization of waste marble dust as an additive in cement production. Mater Des 31:4039–4042 ArticleGoogle Scholar

- Sarkar R, Das SK, Mandal PK, Maiti HS (2006) Phase and microstructure evolution during hydrothermal solidification of clay-quartz mixture with marble dustsource of reactive lime. J Eur Ceram Soc 26:297–304 ArticleGoogle Scholar

- Ergün A (2011) Effects of the usage of diatomite and waste marble powder as partial replacement of cement on the mechanical properties of concrete. Constr Build Mater 25:806–812 ArticleGoogle Scholar

- Aliabdo A, AbdElmoaty M, Auda EM (2014) Re-use of waste marble dust in the production of cement and concrete. Constr Build Mater 50:28–41 ArticleGoogle Scholar

- Hebhoub H, Aoun H, Belachia M, Houari H, Ghorbel E (2011) “Use of waste marble aggregates in concrete. Constr Build Mater 25:1167–1171 ArticleGoogle Scholar

- Shirulea PA, Rahman A,Gupta RD (2012) Partial replacement of cement with marble dust powder. Int J Adv Eng Res Google Scholar

- Vardhan K, Goyal S, Siddique R, Singh M (2015) Mechanical properties and microstructural analysis of cement mortar incorporating marble powder aspartial replacement of cement. Constr Build Mater 96:615–621 ArticleGoogle Scholar

- Ran A, Kalla P, Csetenyi LJ (2015) Sustainable use of marble slurry in concrete. J Clean Product 94(2015):304–311 ArticleGoogle Scholar

- Rai B,Naushad K, Kr A, Rushad T (2011) Influence of marble powder/granules in concrete mix. Int J Civ Struct Eng 1:827–834 Google Scholar

- Belaidi ASE, Azzouz L, Kadri E, Kenai S (2012) Effect of natural pozzolana and marble powder on the properties of self-compacting concrete. Constr Build Mater 31:251–257 ArticleGoogle Scholar

- Aruntas HY, Guru M, Dayi M, Tekin I (2010) Utilization of waste marble dust as an additive in cement production. Mater. Des 31:4039–4042 Google Scholar

- Marras G, Careddu N, Internicola C, Siotto G (2010) Recovery and reuse of marble powder by-product. Global stone congress Google Scholar

- Corinaldesi V, Moriconi G, Taurun RM (2010) Characterization of marble powder for his use in mortar and concrete. Constr Build Mater 24:113–117 Google Scholar

- Karaşahin M, Terzi S (2007) Evaluation of marble waste dust in the mixture of asphaltic concrete. Constr Build Mater 21:616–620 Google Scholar

- Deshmukh JV, Varhade R, Tandel K, Gadekar M (2015) Green cement for sustainable concrete using marble dust. Int J Appl Innov Eng Manage 4:144–150 Google Scholar

- Ergun A (2011) Effects of the usage of diatomite and waste marble powder as partial replacement of cement on the mechanical properties of concrete. Constr Build Mater 25:806–812 Google Scholar

- Binici H, Kaplan H (2007) Yilmaz S Influence of marble and limestone dusts as additives on some mechanical properties of concrete. Sci Res Essay 2:372–379 Google Scholar

- OzturanT ÇeçenC (1997) Effect of coarse aggregate type on mechanical properties of concretes with different strengths. Cem Concr Res 27:165–170 ArticleGoogle Scholar

- Shelke V, Pawde P, Shrivastava R (2012) Effect of marble powder with and without silica fume on mechanical properties of concrete. J Mech Civ Eng (IOSRJMCE) 1:40–45 Google Scholar

- Silva D, Gameiro F, Brito DJ (2014) Mechanical properties of structural concrete containing fine aggregates from waste generated by the marble quarrying industry. J Mater Civ Eng Google Scholar

- Poon CS, Shui ZH, Lam L, Fok H, Kou SC (2004) Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem Concr Res 34:31–36 Google Scholar

- Martins P, Brito DJ, Rosa A, Pedro D (2013) Mechanical performance of concrete with incorporation of coarse waste from the marble industry. Mater Res J Google Scholar

- Coutinho A (1988) Production and properties of concrete. National Laboratory of Civil Engineering, Lisbon, Portugal (in Portuguese) Google Scholar

- Evangelista L, Brito DJ (2007) Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem Concr Compos 29:397–401 Google Scholar

- Tasong WA, Lynsdale CJ, Cripps JC (1999) Aggregate cement paste interface. Part I. Influence of aggregate geochemistry. Cem Concr Res 29:1019–1025 Google Scholar

- Odler I, Zurz A (1987) Structure and bond strength of cement aggregate interfaces. MRS Proc 114:21–27 Google Scholar

- Basheer L, Kropp J, Cleland D (2011) Assessment of the durability of concrete from its permeation properties: a review. Constr Build Mater 15:93–103 ArticleGoogle Scholar

- Metha P, Monteiro P (1994) Concrete: structure, properties and materials. Technology dissemination project Google Scholar

- Amorim P, Brito DJ, Evangelista L (2012) Concrete made with coarse concrete aggregate: influence of curing on durability. ACI Mater Jvol 109:195–204 Google Scholar

- Andre A, Brito DJ, Rosa A, Pedro D (2013) Durability performance of concrete incorporating coarse aggregates from the marble industry Google Scholar

- Binici H, Shah T, Aksogan O, Kaplan H Durability of concrete made with granite and marble as recycle aggregates. J Mater Proc Technol 208:299–308 Google Scholar

Author information

Authors and Affiliations

- School of Civil Engineering, KIIT, Bhubaneswar, Odisha, India Srishti Saha, Tribikram Mohanty & Purnachandra Saha

- Srishti Saha